This article, written by Regional Program Director Zhenzhen Xu and Program Director Megan McLeod, highlights the efforts of AWS certified site operators Avary Holding and Ecolab, as well as AWS member Want Want Group in mitigating COVID-19 impacts.

The COVID-19 (coronavirus) pandemic has seriously disrupted business and the global economy. Many businesses will not survive. However, some have proactively responded to the emergency and are adapting to the unfolding situation.

News and studies from sustainable business and industry sectors are showing the resilience and ability of sustainability-minded businesses to adapt, along with high levels of community care and stakeholder trust.

A World Business Council for Sustainable Development (WBCSD) analysis of its member companies indicates that businesses with environmental, social and governance (ESG) considerations exceed major stock exchange benchmarks by 4.3–9.4% and show stronger than average rebounds from crisis lows in March.

Responsible businesses understand environmental and social risks and values and many invest in ESG by adopting sustainability and industry standards that promote holistic approaches including behaviour change, multi-stakeholder engagement, collective action and continual improvement.

In China, factories implementing the AWS Standard, the globally recognized framework for water stewardship, have adopted response measures to the pandemic, alongside future resilience and sustainability planning. These sites have taken the initiative to protect the health of their workers, and the wider community, as they return to production.

The pandemic highlights the importance and preventive power of water, sanitation and hygiene (WASH) to human health and well-being – one of the five outcomes of the AWS Standard. Good hygiene, including handwashing with clean water, is the first line of defence against COVID-19 and other viral diseases. It also highlights the important role and responsibility of business to protect the health of their workers, as workplaces are areas where people interact for extended periods of time and thus present occupational exposure risk.

Avary Holding Guarantees the Healthy Return of Thousands of Employees

Following the COVID-19 shutdown over Chinese New Year in late January 2020, micro-electronics manufacturer Avary Holding (Avary) was one of the earliest operations to return to production. Fully resuming production in February, Avary recorded a zero infection rate among all its employees. A series of measures were put in place to ensure a safe work environment for all staff from the outset of their return to work.

For a large manufacturing site, it important to implement precise and careful management measures —from employees’ return to the factory, to daily management and emergency response. Most employees were dispersed in their hometowns for Chinese New Year, which presented one of the biggest challenges in managing their return to work. Avary developed Standard Operating Procedures (SOPs) covering the following eight aspects:

- Staff awareness and training: infection prevention training for all staff.

- Returning employee management: rules and procedures on virus testing and quarantine for employees returning to work.

- Workplace disinfection: routine disinfection of all common areas (e.g. canteen, public dormitory areas, offices, and shoe changing areas) and facilities (e.g. elevator buttons, door handles, coaches, and commuter cars).

- Workplace ventilation measures: using the air conditioning systems in accordance with updated industry guidelines, isolation of areas, using fresh air mode on air conditioning systems and opening windows to improve ventilation, and where required, disinfection of return air ducts.

- Body temperature measurement: daily body temperature measurement for all employees.

- Face Mask: provision of face masks and requirement to wear a face mask when entering the factory.

- Employee care: using a mobile app for daily health check-ins.

- Emergency handling: establishing an emergency notification group and procedures for reporting and emergency case handling.

In addition to instituting new SOPs, Avary began producing disinfectants for onsite use. To minimize the risk of spontaneous combustion associated with using alcohol-based disinfectants, Avary purchased sodium hypochlorite generators to produce bleach. This helped to reduce demand on vital public disinfectant supplies and ensured a constant availability of freshly made bleach.

As a precautionary measure, Avary also adopted medical waste management procedures to safely manage the collection and disposal of used face masks, protective clothing and disposable gloves. These procedures include:

- Having specially designated bins that are regularly disinfected

- Centralised storage and containment in the waste storage area

- Marking medical waste as hazardous waste for disposal by licensed companies

Ecolab mobilises resources and Expertise to Support Virus Control in Wuhan

The city of Wuhan emerged as the epicentre of the fight against coronavirus in China. To alleviate the shortage of cleaning and disinfection equipment at the Central Hospital of Wuhan, hygiene and sanitation provider Ecolab donated a set of endoscope reprocessing equipment, as well as cleaning and disinfection materials worth CNY 430,000 (AUD 86,000). The equipment and materials were dispatched on 1 April 2020 to the Central Hospital of Wuhan.

Ecolab has also collaborated with the hospitality sector to raise awareness on infection prevention. Using in-house expertise, Ecolab developed and published guidebooks on preventing virus spread during the reopening of the hospitality sector. To improve public awareness around the concept of hand hygiene, Ecolab launched a public campaign for handwashing in partnership with major restaurants in China.

To engage with their employees and document this unforgettable and unprecedented period for the company, Ecolab developed a story book detailing their pandemic response.

Want Want Group Responds to Changes in Supply Chain Production

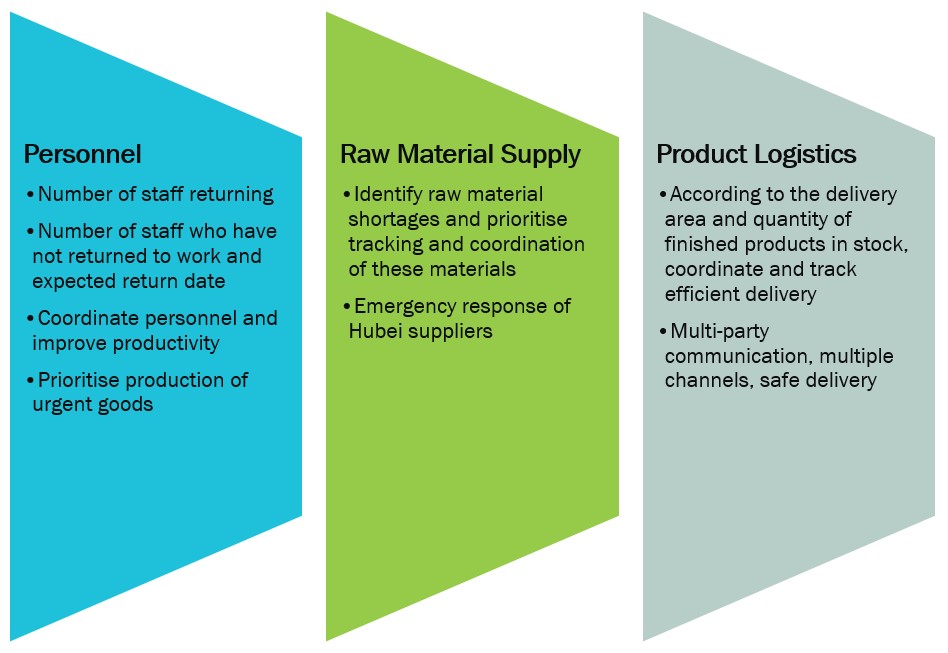

In the process of gradually restoring production, businesses face challenges in their supply chain, inventory management, transportation and sales. Want Want Group, one of the largest snack food producers in China, identified risks in personnel management, raw material supply and logistics in the recovery of its production and sales. By enhancing internal and external coordination throughout its business value chain, Want Want closely monitored key risk indicators to optimise production planning and quickly respond to changes.

Want Want has also started producing disinfectants for onsite use. Excess supplies of disinfectants were made available to local communities at no charge through dispensing stations. Want Want had also donated disinfectant machines to local hospitals and government departments.

Although in China the first wave of COVID-19 has now passed, the risk of imported cases and localised outbreaks remain. Like many companies, Want Want is learning and recovering from the crisis while planning for a new normal. Key to this transformation is innovation and resilience-building. Want Want’s efforts focus on the following aspects:

- Establishment of a group-level emergency response team;

- Developing long-term reserves of emergency supplies;

- Supply chain flexibility and resilience;

- Acceleration of production automation; and

- Intelligent office solutions.

Join the AWS Community

As we begin to emerge from the pandemic, it is clear that the need to work together to ensure the sustainability of our water resources has never been greater. Join the AWS Community today at waterstewardship.org.au/membership.